⚖️ Precision Driven Operational Efficiency & Customer Satisfaction

📌 Why It Matters:

Automated systems can occasionally omit important details, especially with complex or irregular pallet loads. Pallet Weight Tracking offers control when warehouses need to capture accurate data, reflecting the actual conditions in the warehouse.

Improving the accuracy of shipping records to support compliance and smoother warehouse operations is paramount. With precise control over the data, businesses can avoid costly errors and build stronger customer relationships.

What It Does:

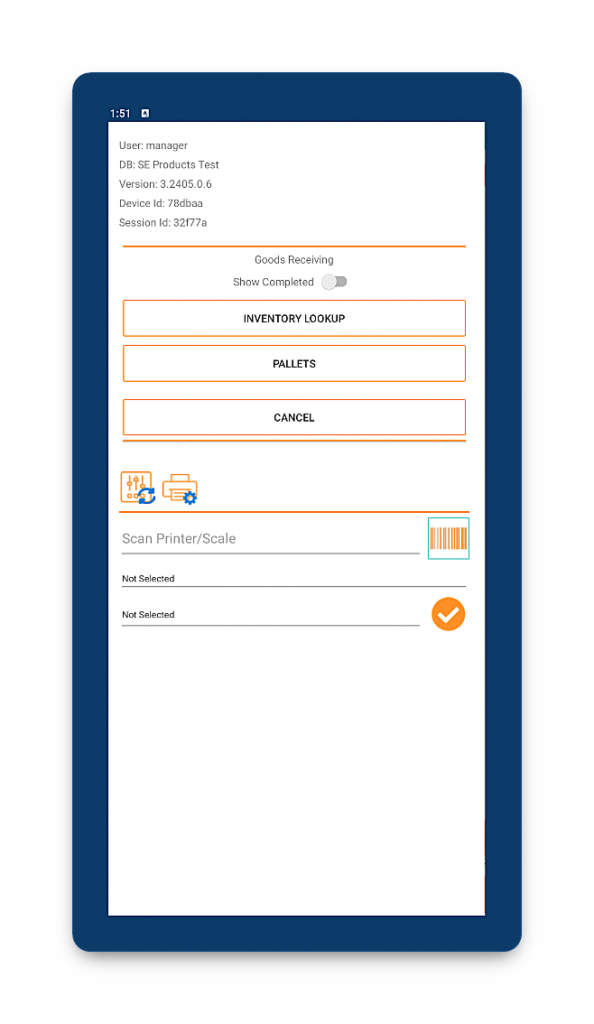

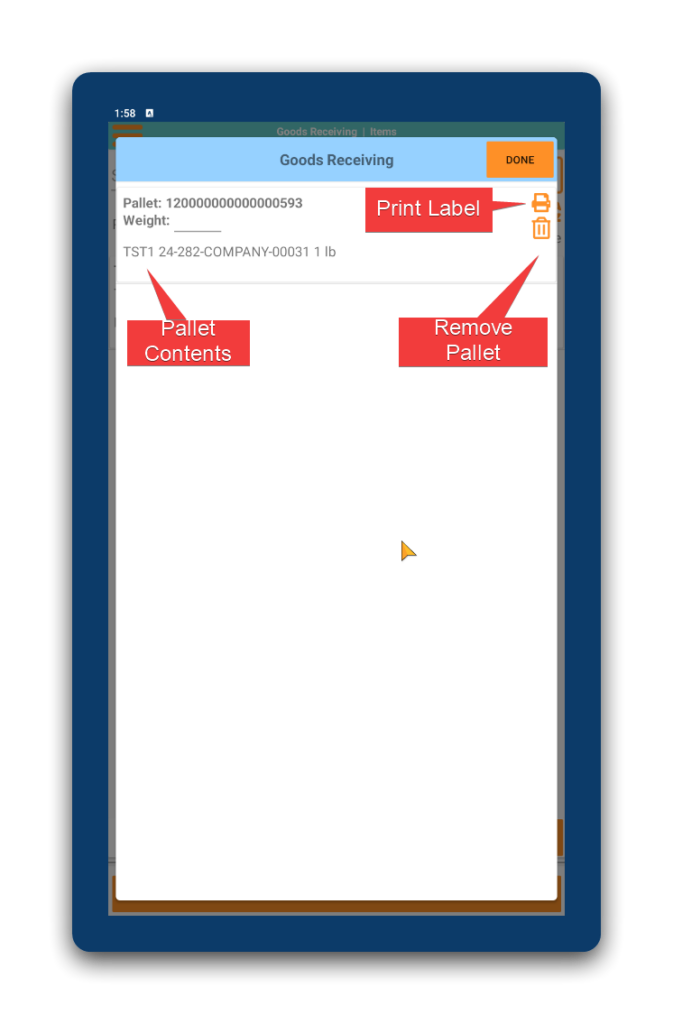

Users can enter pallet weights manually through the pallet tile or a dedicated window in the pallet list screen. The weight is saved in the pallet table and can be accessed to generate labels, reports, or other downstream processes. The innate flexibility of the feature helps businesses capture the precise weight needed for operations, avoiding errors that could disrupt shipping or inventory management.

How It Works:

Operators input the pallet weight into the WMS+ interface, where the data is immediately available for use in warehouse processes like label generation, reporting, and inventory management, signifying all relevant documentation reflects the real-world weight of each pallet, improving decision-making and operational accuracy.

How It Benefits You:

Accurate pallet weight data improves efficiency across multiple areas of your operation. Pallet Weight Tracking guarantees shipments reflect real-world conditions, diminishing the risk of costly shipping errors. Manual input of precise data avoids discrepancies in inventory tracking, resulting in expedited workflows and reliable inventory management.

If compliance standards are an everyday concern or you have challenges maintaining customer satisfaction, maintaining control on weight data grants you the tools optimize your warehouse processes without disruptions.

🌍 Real-World Scenarios and Benefits for Partners and Their Customers:

🧩 Handling Irregular or Mixed Loads:

Automated systems can struggle to capture the correct weight in warehouses dealing with mixed or irregular loads. Manually entering pallet weights confirms the data accurately reflects the actual weight of each load, reducing the chance of shipping errors or costly returns.

Benefit: Improves shipping accuracy and prevents errors that might impact the customer experience.

🏗️ Small to Medium Warehouses Without Full Automation:

For smaller operations or those without the budget for full automation, Pallet eight Tracking provides a cost-effective solution to maintain accuracy without overhauling existing systems. Operators can capture the exact weight data needed for daily operations without expensive upgrades.

Benefit: Offers a low-cost method of maintaining accuracy and control over inventory and shipping processes.

✅ Compliance in Regulated Industries:

Industries like pharmaceuticals or food often require precise weight tracking to meet regulatory standards. Pallet Weight Tracking guarantees all shipments meet compliance needs by manually recording accurate pallet weights; it helps businesses avoid fines and maintain transparency.

Benefit: Supports meeting strict industry regulations by providing an accurate audit trail of pallet weights.

🚚 Quick Turnaround for Cross-Docking:

In fast-paced cross-docking environments where pallets are quickly unloaded and reloaded, automation may not be available at every station. Pallet Weight Tracking helps maintain accuracy during quick transitions, reducing the need for additional checks.

Benefit: Supports faster processing times without compromising accuracy, allowing for a quicker turnaround and fewer operational bottlenecks.

📊Data Availability for Reporting and Labels:

Inaccurate weight calculations can cause discrepancies in recorded pallet weights, impacting shipping and inventory management processes. Manually entering pallet weights means the recorded data reflects the actual weight of the pallets. Pallet weight accuracy negates errors in shipment preparation and inventory tracking for more efficient warehouse operations.

Benefit: Helps businesses maintain accurate inventory records, improving operational efficiency to facilitate customer order fulfilment.

A Heartfelt Thanks to Our Team

Pallet Weight Tracking isn’t just a feature – it’s a leap toward greater precision and control for our partners and their customers. Thanks to your dedication, WMS+ v3.2405 now gives businesses the accuracy they need where automated solutions may fall short.

This update is a direct result of your problem-solving mindset and commitment to creating practical, impactful solutions. You’ve given our partners the tools to manage their operations more effectively and deliver the reliability their customers expect.

To everyone who made this possible, thank you for turning a simple need into a powerful advantage. Together, we continue Making Business Simple.

The Softengine Web team:

We’re excited to collaborate with you, constantly pushing the boundaries to deliver solutions that don’t just meet your expectations—they shatter them.

As a family-run business, our dedication lies in ensuring your success and fostering a mutually beneficial partnership. We are deeply committed to providing products and services that address real-world challenges, enabling both you and your clients to thrive.

Making Business Simple.

To Our Valued Partners

At Softengine, precision and flexibility are essential in logistics. That’s why we introduced Pallet Weight Tracking in WMS+ v3.2405—to give you greater control over how pallet weights are recorded, especially when automation might not capture the full picture.

Why focus on this? Because accuracy is everything when it comes to logistics, and Pallet Weight Tracking gives you the flexibility to meet those demands. Whether it’s ensuring compliance or improving operational efficiency, this feature helps you reduce costly errors and improve how you manage your data.

As always, we’re committed to supporting your growth and Making Business Simple.

🛠️

Tell us how we can make our products even better…

Have a suggestion to enhance your experience with Softengine Web?

We’d love to hear from you—submit your ideas here and help shape future updates!