📦

New Features for February in WMS+ Version 2403

📦🔖

Record Additional Information about your Batches when Receiving Goods Inwards with UDF Support

⏱️📇

Streamline Inventory Counts with Automatic Confirmation and GS1 Weight Capture when Scanning, Saving Time and Effort

🍗🧀🥩🐟

Catchweight Solution Refined: Comprehensive Handling from Picking to Counting.

⚖️📦

Seamless Scale Integration: Simplifying All Weighing Tasks with WMS+

🚀🏭

Streamline Variable Weight Picking: Effortlessly Weigh and Print with Pick Station Integration

🧤❄️💧📲⚖️👍

Boost Productivity with Scan to Weigh: Effortless Scanning, Even in Wet Rooms or Freezers, with Gloved Hands

🖨️⚖️

Easy Peripheral Setup: Select Default Printer and Scale with Ease

🏷️🔍

Transform Your Labeling Process: Unlock a World of Possibilities with Custom Label Contexts

💰📋

Effortless Expense Tracking: Copy Freight, Tax and Additional Expenses to your GRPOs on Receipt

📦🔖

Record Additional Batch Attributes when Receiving Goods Inwards with LotNumber UDF Support

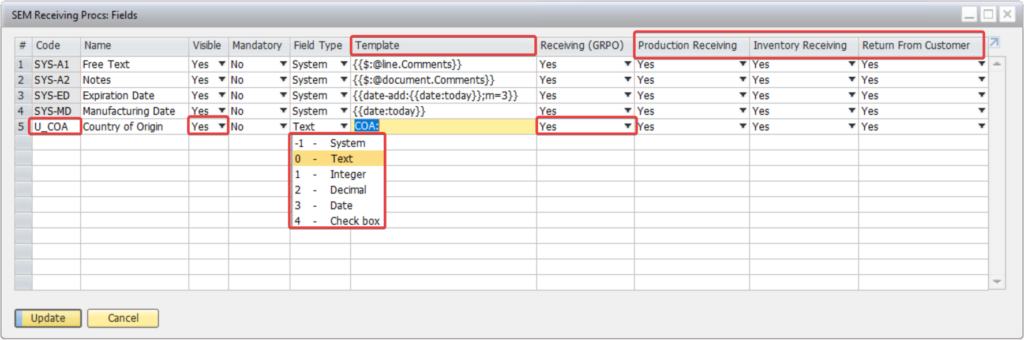

Need to capture more than just an expiration date and a couple of batch attributes when receiving goods inwards?

This feature is great for anyone who manages their inventory in batches and wants to record specific features of the lot/batch when receiving, for example, maybe you want to record the Country of Origin or the Manufacturer Lot Number.

Simply setup your user-defined field in SAP Business One, and then head to the WMS+ Receiving Process Fields: in Tools →User-Defined Windows → SES_SEM_PROCS_CF and define your new attributes there:

⏱️📇

Streamline Inventory Counts with Automatic Confirmation and GS1 Weight Capture when Scanning, Saving Time and Effort

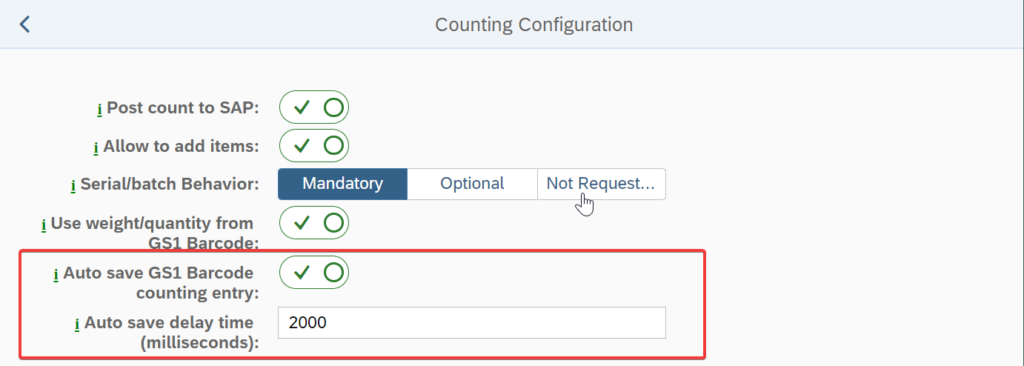

Now, when you scan an item, the system automatically confirms the count, eliminating the need for manual entry. This update includes a customizable delay option for accurate, efficient scanning. Plus, for items with a GS1 label, WMS+ now captures the weight automatically, further reducing manual input and streamlining your workflow.

🍗🧀🥩🐟

Catchweight Solution Enhanced: Comprehensive Handling from Picking to Counting

Experience enhanced accuracy and efficiency with improved “To Pick” quantity calculations and streamlined processes for Picking, Shipping, and Counting.

Count catchweight items with ease, accounting for both case and inventory units. Customize weight selections with options for total, standard, or average weight and total GS1 support for serialized cases.

Embrace enhanced control and precision in catchweight management.

⚖️📦

Seamless Scale Integration: Simplifying All Weighing Tasks with WMS+

Simplify the entire logistics workflow with our seamless integration of digital scales into WMS+, enhancing efficiency across various operations.

From receiving goods inward to taking receipt from production, picking from bulk containers, and counting inventory, our scale integration ensures accurate shipments and precise inventory management every time.

Say goodbye to manual calculations and tedious screen inputs while saving valuable time and minimizing errors throughout your logistics workflow.

🚀🏭

Streamline Variable Weight Picking: Effortlessly Weigh and Print with Pick Station Integration

Streamline your picking process with our innovative station solution. Simply scan the barcode on your weigh station, equipped with a scale and label printer, to seamlessly weigh and label variable weight items like fish or meat.

Effortlessly trigger the scale reading and set the printer for accurate, on-the-spot labeling, enhancing efficiency and precision in your operations

🧤❄️💧📲⚖️👍

Boost Productivity with Scan to Weigh: Effortless Scanning, Even in Wet Rooms or Freezers, with Gloved Hands

No More Hands on Screens! With Scan to Weigh, simply scan your product, place on the scale, and scan a barcode on the scale to trigger the read into WMS+, eliminating the need for manual data entry or touching the screen during the picking process. Enjoy a completely hands-free workflow, from item identification to precise weighing, for enhanced efficiency and convenience.

🖨️⚖️

Easy Peripheral Setup: Select Default Printer and Scale with Ease

With our new peripheral selection feature, just select your default printer from the list. No more database configurations or label-to-printer configurations needed. Enjoy seamless printing to your chosen printer until you decide otherwise.

🏷️🔍

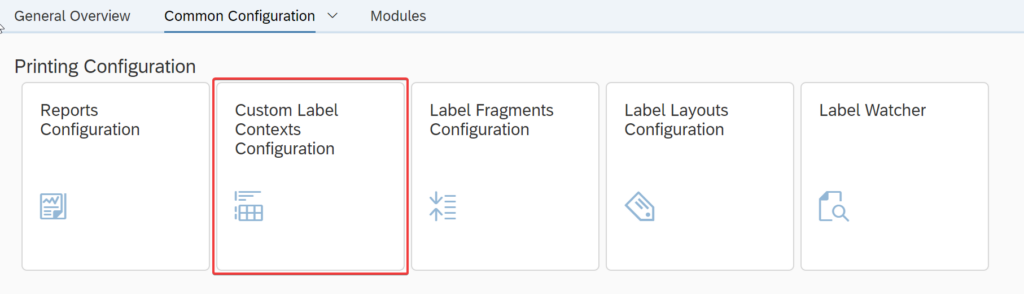

Transform Your Labeling Process: Unlock a World of Possibilities with Custom Label Contexts!

Gone are the days of limited information for your inventory labels. Now, dive deep into your product details by collecting data directly from SAP Business One. From country of origin to species and more, tailor your labels to fit your unique needs.

Need to print multiple labels? No more guesswork – use Item Master Data to calculate the exact number of labels needed for every job.

💰📋

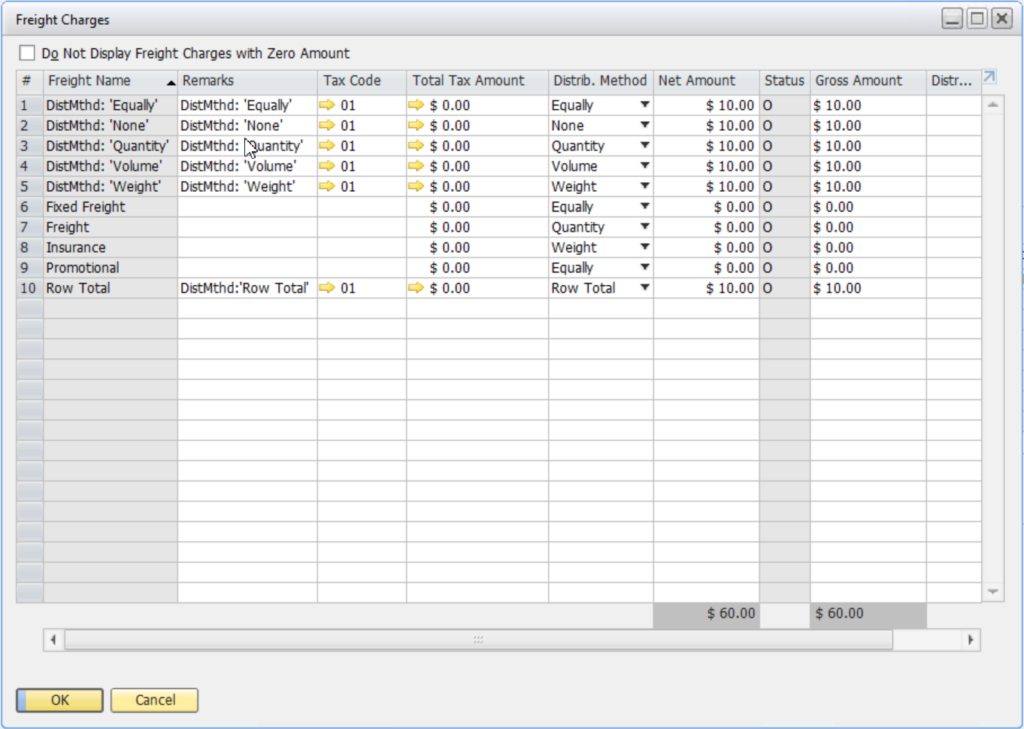

Effortless Expense Tracking: Copy Freight, Tax and Additional Expenses to your GRPOs on Receipt

Gone are the days of manual entry – now utilize standard SAP Business One logic to automate expense allocation. With various distribution and drawing methods available, easily manage and trace expenses, keeping your financials organized and accurate.

Other Improvements

🏚️

Streamlined View: Inactive Warehouses are now Hidden in WMS+

📦✨

Enhanced Shipping Precision: Itemize Package Contents Individually

⏱️

Efficient Counting and Enhanced Accuracy: Automate Scan Confirmation and Customize Result Delays for Enhanced Productivity and Mark Count Lines as Zero for Precise Inventory Counting

🎯

Enhanced Parsing Control: Choose the Priority of AI’s (30) and (3202) when present in the same barcode for Improved Scanning Accuracy

⚖️

Train your Team to Use WMS+ Scale Integration with Demo Mode: A New Setting for Scales to Provide Test Values Instead of Real Weights

📜

Improved DSD Invoicing: Display Card Comments on Invoice Headers for Enhanced Communication between Sales and Driver

🖨️

Enhanced Visibility and Troubleshooting: Printer Information Now Included in Label Watcher

🗑️

Enhanced Functionality: Delete Feature Implemented for Process Settings, Allowing Removal of Unwanted Configurations

🌐

Improved Accessibility: Access the WMS+ Admin Panel with Microsoft Edge

Known Issues Resolved

Catchweight

- Enhanced picking accuracy by ensuring that the number of catchweight cases “to pick” are displayed in “actual cases” rather than “standard cases”.

- Improved our user experience by displaying the selected weight of catchweight items in the “Batch Entry Screen”.

- Ensured that WMS+ accurately updates the “sales order” after the picking process by fixing issues that could have resulted in an incorrectly picked quantity being posted.

- Ensured accurate picking and shipping processes by fixing an issue that could have resulted in discrepancies on the batch allocation screen.

- Boosted productivity by addressing performance issues that could have caused delays in the picking and shipping process.

- Enhanced order accuracy by aligning the “To Pick” quantity calculation with “actual cases” rather than the “standard case” in the shipping process.

- Improved inventory management accuracy by recalibrating the “Over Pick Counter” evaluation.

- Ensured precision in shipping selections by fixing an issue that could have caused the loss of decimal places.

- Improved flexibility in the picking process by removing limitations on the “To Pick” quantity.

- Enhanced inventory accuracy by properly subtracting “Picked” quantity from “To Pick” quantity in “actual case”.

- Enabled flexible weight allocation for catchweight items, ensuring accurate distribution.

Counting Optimization:

- Streamlined counting process by enabling counting with serialized items.

- Enhanced counting process for the team counting feature to allow items to be marked as “zero” (i.e. non-available to count), improving efficiency.

- Simplified counting process by removing mandatory batch number requirement for zero quantity counts.

Custom Contexts and Query Manager:

- Improved system functionality by fixing an issue in the QueryManager to ensure proper deployment of the query to the client.

Picking Enhancements:

- Enhanced GS1 scanning process by fixing issues with the batch allocation window to ensure controls are available.

Labeling Improvements:

- Streamlined label creation process by displaying all relevant folders in the query picker.

- Improved troubleshooting capabilities by adding printer information to the Label Watcher.

- Improved local printing process by fixing an issue that could result in the printer selection not overwriting the default printer in Label Watcher.

Shipping Enhancements:

- Ensured accurate shipping selections by fixing issues that could cause the entire contents of a case record to ship when only a case was selected.

- Ensured accurate shipping of catchweight items by fixing issues that prevented all items on the license plate being drawn to the delivery document.

Warehouse Management Improvements:

- Enhanced data integrity by fixing issues that could result with item records not being properly written to the license plate tables upon license plate creation.

Production Process Enhancements:

- Improved the issue to production process by fixing issues that could prevent the addition of lines and blocking additional issues.

- Improved document visibility by fixing issues causing documents to open as “empty”.

- Ensured complete document visibility by fixing missing completed rows in production documents.

- Enhanced error handling by resolving irrelevant ‘Can’t over-pick hidden line’ error.

Miscellaneous Enhancements:

- Improved overall accuracy by fixing an issue that allowed a user to use the “back” button on the device to override critical “processing” modals allowing the user to resubmit the request, resulting in duplicated transactions such as multiple inventory transfers of the same item when picking.

Special thanks

We are especially proud to acknowledge all the people that have made this release a reality. Without our teams of dedicated development and product professionals, and of course, you, our partners, this release would not be possible.

Thank you, team, for your hard work, dedication, and expertise that have made this release a success, and something we can be truly proud of.

The WMS+ team:

We are proud to serve you and we’re committed to continuing to deliver products and services that exceed your expectations.

As a family-run business, our dedication lies in ensuring your success and fostering a mutually beneficial partnership. We are deeply committed to providing products and services that address real-world challenges, enabling both you and your clients to thrive.

Your success is our success.

🛠️

Tell us how we can make our products even better…

Have an idea what might make your life easier in WMS+? Please feel free to submit it here.