🚀

Our WMS+ Journey So Far…

Introducing Softengine’s

Flagship Warehouse Management Solution

Packed with cutting-edge features and smarter tools, this is hands-down our best version yet! 🌟 Whether you’re streamlining inventory, improving traceability, or enhancing operational efficiency, WMS+ Version 2405 sets the gold standard for warehouse management.

Get ready to revolutionize the way you work. 💼✨

📚

Where We’ve Been, What We’ve Learned, and How We’ve Improved

Explore the journey of WMS+ over the past two years.

Discover key updates, enhancements, and milestones in our Release Notes Archive

📜 August 2024 – WMS+ Version 2404

📜 February 2024 – WMS+ Version 2403

📜 May 2023 – WMS+ Version 2304

📜 March 2023 – WMS+ Version 2302

📜 November 2022 – WMS+ Version 2211

📱

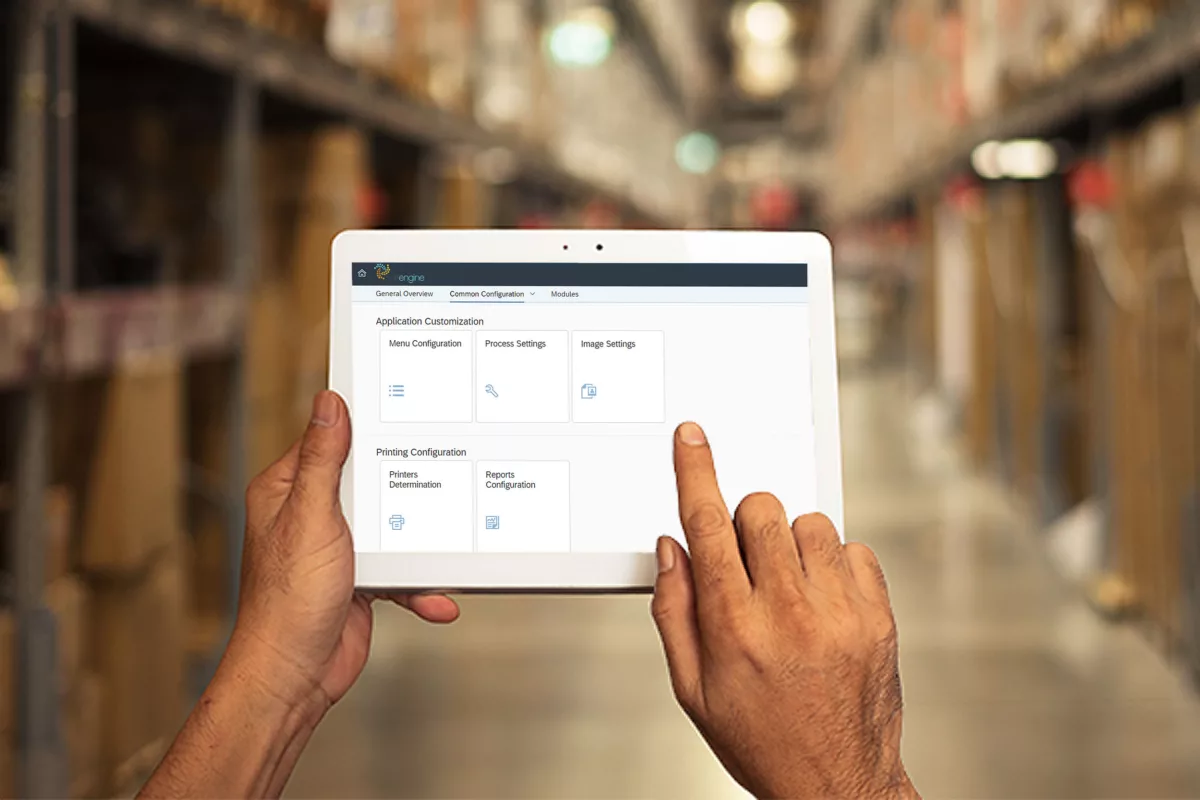

Explore WMS+ and Get Familiar with Our Intuitive UI

👀

Take a closer look at WMS+ and experience a user interface designed for simplicity and efficiency. Our UI overview is your guide to navigating key features, ensuring you’re ready to boost productivity and streamline your warehouse operations.

📦✨

Dive in and discover how WMS+ empowers you to manage inventory, track batches, and optimize workflows—all with ease and precision.

⬇️⬇️⬇️

📦

Maximize Your Warehouse Operations

WMS+ is packed with features designed to simplify your business operations.

Learn not only how to use the software but also the best practices to optimize workflows and boost efficiency.

Start a course below to get started!

⬇️⬇️⬇️

What else can WMS+ help you with?

Inbound operations

- Receiving goods from a Purchase Order, or a Reserve Invoice.

- Receiving goods from a Production Process.

- Receiving goods from a Customer Return Request.

- Receiving goods from an Inventory Adjustment (found items).

Movement operations

- Transferring goods from bin location to bin location.

- Transferring goods by task (transfer request).

- Transferring goods by task for production staging (transfer request).

- Picking and staging goods for specific orders (sales orders).

- Picking and staging goods for pick lists (compounded orders or split orders).

Outbound operations

- Shipping goods out to fulfill a Sales Order.

- Shipping goods out to fulfill a Picked List.

- Shipping goods out to fulfill a Vendor Return Request.

- Issuing goods to a Production Order.

- Issuing goods out of the warehouse from an Inventory Adjustment (spoiled / written off items).

Counting operations

- Counting the contents of a bin location.

Direct to store distribution operations

- Selling items directly from a delivery vehicle.

- Taking check or cash payments.

- Capturing signatures for proof of receipt.

- Printing receipt roll as proof of purchase.

- Taking returns from a customer.

- Creating a sales order for your customer or for future replenishment

Additional features to help your team with their tasks

Speed, ease, and accuracy using the power of GS1 scanning

- Benefit from the speed, ease, and accuracy of GS1 enabled scanning over all receiving, moving, outbound, and counting operations.

- Easily receive goods and capture attributes such as lot number and expiration date in one scan directly from your vendors labels.

- Accurately select goods in your warehouse by scanning the GS1 enabled tag ensuring your team has the correct item and batch for the order.

Catalog inventory with GS1 label printing

- No vendor labels, no worries…

- Print GS1 enabled QR Code labels directly from the device to catalog incoming inventory and ensure that items can be scanned and selected throughout the rest of the inventory lifecycle.

Create or reprint damaged inventory labels directly from the device

- WMS+ allows your team to create new labels anytime you scan a bin location.

Manage your inventory wisely using batch attributes

- WMS+ can collect, manage, and display batch attributes directly from the device.

- Need to catalog a specific property for an item, such as an expiration date, manufacturing date, or any other property (such as country of origin)? WMS+ can be configured to collect this information anytime goods are received into the warehouse.

- Even better, if this information is needed when moving, picking, or issuing into a process WMS+ can be configured to display this information when looking up inventory in bin locations.

Speed up your receiving process using auto lot number

- Want to speed up your receiving process and provision advanced inventory and traceability? WMS+ can be configured to automatically create a lot number each time goods are received into the warehouse. Typical examples are:

- Julian Date + Document Number + Sequential Number

- (22-251-001-001)

- Standard Date + Document Number + Sequential Number

- (20220909-001-001)

- Helping you understand what lots you have in your warehouse

Manage your inventory more efficiently using by managing item expiration date

- Do you constantly write of inventory due to spoilage or expiration? Do you employ first to expire first out but struggle to find the right batch? Or do you need to offer your clients guaranteed shelf life?

- Softengine’s WMS+ paired with SAP Business One provides the ability to capture expiration date on goods receipt, or even better auto allocate expiration date based on item shelf live when receiving from production.

- Using this information item/lot combos can be allocated to tasks in WMS+, paired with Guided Picking, and GS1 scanning you can ensure that the correct batch for the correct order and that the soonest to expire is the batch that is actually leaving your warehouse.

Move and containers and contents easily using license plating

- Tired of scanning multiple items when wanting to transfer containers around your warehouse? License plates in Sofengine’s WMS+ give’s your team the ability to label a container with a QR Code enabled ID. Everything in the container can be moved from bin to bin or issued into any operation via one scan.

- Even better, items can be picked from a license plate and issued to a task in WMS+ leaving the container and remaining contents intact.

- Ideal for saving time when working with pallets that contain multiple stock keeping units.

Document tasks to ensure warehouse transparency

- Need traceability or to document important information when completing a task? WMS+ provides the ability for your team to add their remarks to any task to ensure that the warehousing and back-office team are always in sync.

Easily find storages locations using location suggestions

- Don’t know where an item should live when transferring or storing goods? Or need to find an empty bin location? WMS+ provides the ability to suggest the default bin location for your item, or item group, whilst identifying any empty bin locations.

Manage and track multiple units of measure using catch weight

- Buy in cases and sell by weight?

- WMS+ helps you to manage your cases and the weight value simultaneously.

Quickly find a batch using quick move

- Don’t know which bin location a batch or container should be located in? Easily tidy up by scanning the GS1 QR Code to automatically select the item or give a list of bin locations where the item should be.

Style WMS+ with your own branding

- Add your own logo to the WMS+ splash screen using the WMS+ admin console.

Operate WMS+ in Spanish

- Do members of your team speak different languages? WMS+ can now be operated in English and Spanish.

*Some features require additional configuration to activate. Please see your account manager for more details.