How to make your production simple using Softengine’s Production Room

Are you a meat or fish cutter, or a deli operative looking for a way to easily weigh prepare your finished cuts for your customer? Maybe you are cutting a filet mignon from the tenderloin, cutting a fillet from fish. Maybe you’re slicing cold cuts or cheese to order. You might even be in a manufacturing industry producing one off items.

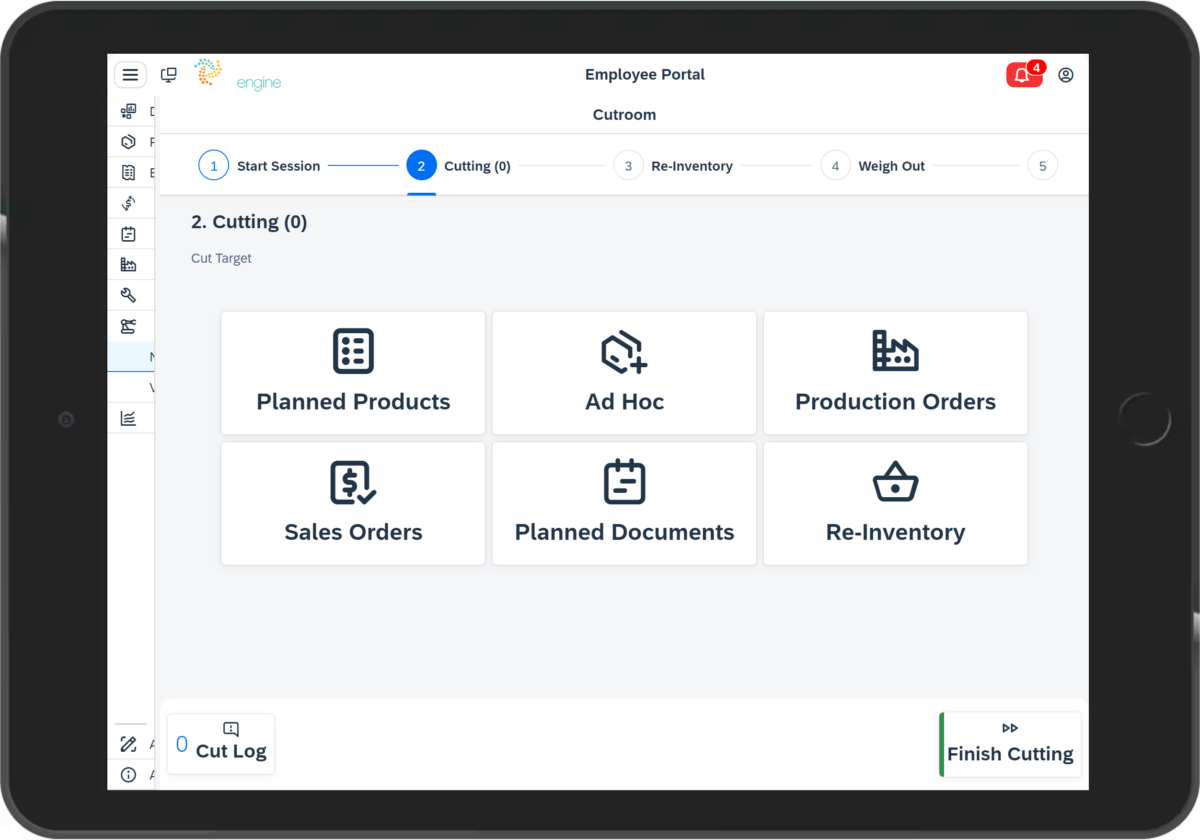

Softengine’s Production Room facilitates ad-hoc production runs:

- Simply select your finished product from a list of production items (the target).

- Select your raw material (the base), and start your cutting.

- Production room connects to a scale and a label printer via PrintNode and allows for easy weigh out, and GS1 label printing to record finished products.

Production Room handles the entire SAP Business One Document creation process and creates the underlying work orders to transact against, auto issues components based on your recipe (integrated with Softengine recipe manager) and takes receipt of newly created goods linking together the transactions and maintaining full traceability without needing to even log into SAP.

Also, if you are cutting to a baseline yield target or industry standard yield, then Production Room provides the ability to weigh out any remaining base material to evaluate how your production compares to your target conversion. Production Room automatically receives back into inventory any base material that was not used in the production if your production run exceeds cutting expectations.